Ecowende, CAPE Holland and GBM Works pioneer innovative monopile installation techniques to reduce underwater noise

Thursday 11 December 2025

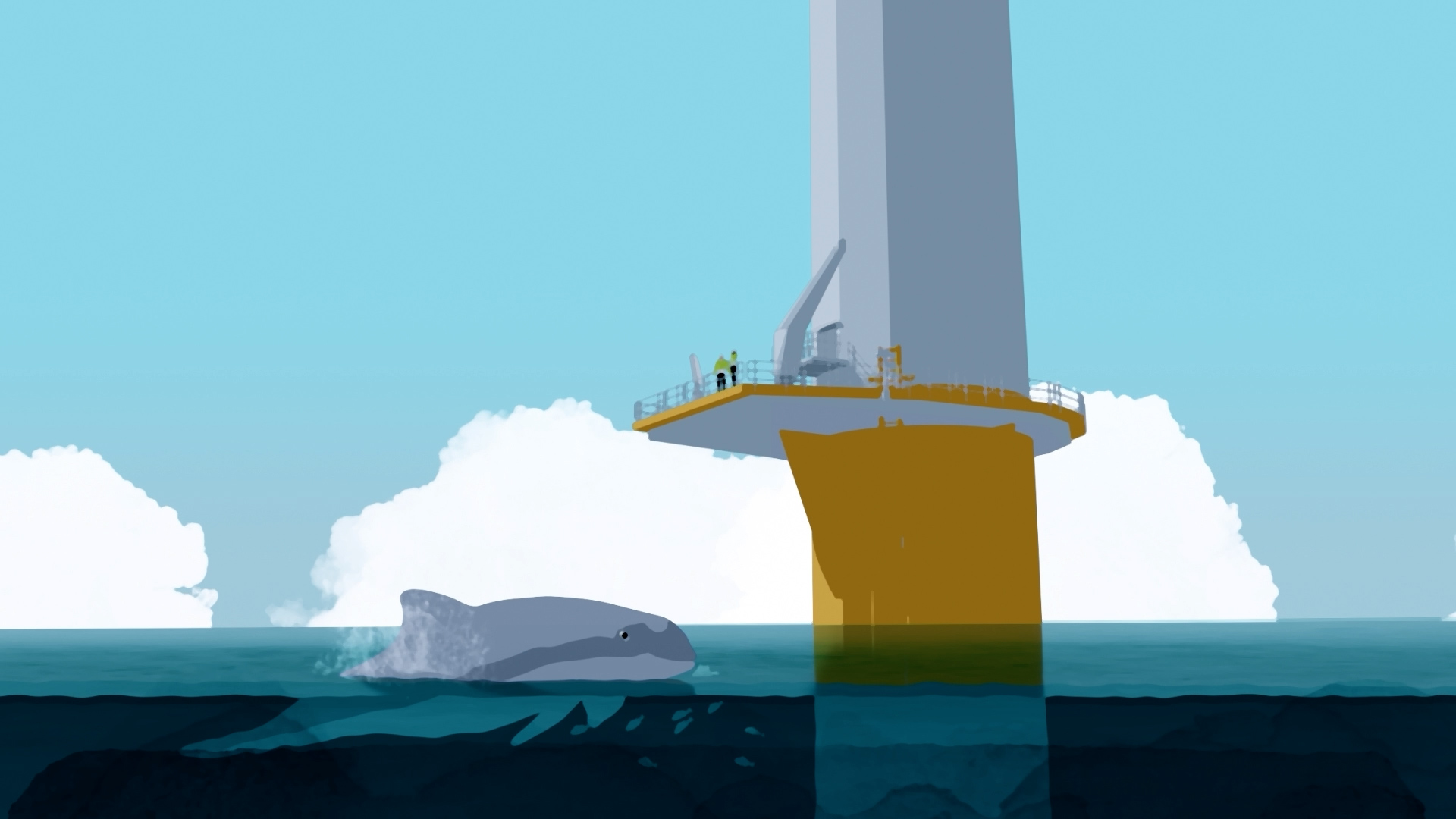

Ecowende, in collaboration with CAPE Holland and GBM Works, is pioneering innovative installation techniques for XXL monopiles at the Ecowende offshore wind farm. The project focuses on vibro-based technologies designed to reduce underwater noise and minimise impacts on marine life during monopile installation.

As offshore wind turbines grow larger, so do their monopiles. Traditional impact pile driving produces powerful underwater sound waves that can disturb marine mammals, such as harbour porpoises. Even with mitigation measures like bubble curtains and resonator arrays, underwater noise remains a concern. Ecowende and partners have therefore explored alternative and innovative installation methods with the aim to reduce the ecological footprint of wind farm construction. These innovative methods will soon be demonstrated at our wind farm, where Van Oord’s offshore installation vessel Boreas began construction on Wednesday 3 December.

Innovative technologies in action

Ecowende demonstrates two cutting-edge methods:

1. Vibro Technology (CAPE Holland)

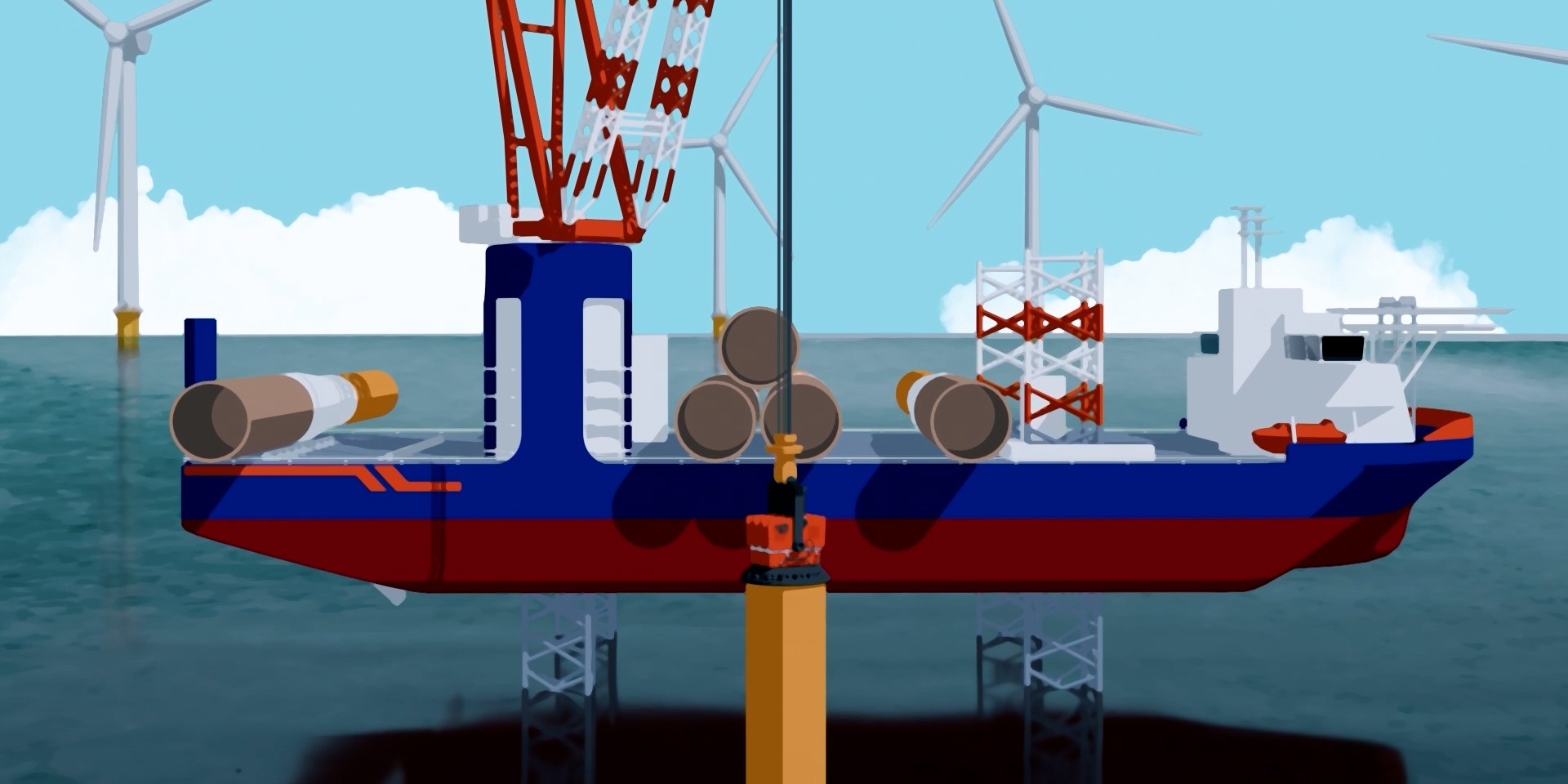

The CAPE VLT-640 Quad uses vertical vibrations to temporarily reduce soil resistance, allowing monopiles to sink under their own weight. The CAPE Vibro Lifting Tool (CAPE VLT) has already been successfully deployed to install hundreds of monopiles on recent large-scale offshore wind projects on both sides of the Atlantic, establishing it as a proven commercially mature technology for specific site conditions.

CAPE Holland will supply and operate the CAPE VLT to Van Oord, who is planning to use it to drive the monopiles into the seabed with the Boreas installation vessel at six selected test locations. In the Dutch North Sea, the relatively dense sands present a major challenge to install the monopile by vibro-driving – making the Ecowende project an ideal setting to assess the capabilities of vibro-based methods in the most demanding ground conditions.

2. VibroJet® Technology (GBM Works)

At three of the test locations, VibroJet® is planned to be applied, including the Vibro Technology. This approach combines vertical vibrations with controlled water jets inside the monopile, fluidising the soil inside the monopile to further lower soil resistance. This increases the likelihood of achieving full depth while potentially generating lower underwater noise than conventional impact hammers.

"Noise regulations for offshore wind projects are becoming increasingly strict, while wind turbines continue to grow and monopiles become heavier, generating more underwater noise," explained Dick van Wijngaarden, Business Development Manager at CAPE Holland. "Vibro Technology has already demonstrated its capability and significant ecological benefits in commercial projects, but we need to fully understand how the technology performs in dense to very dense soils to apply it reliably and effectively and to continue its development for future projects."

The innovative combination of Vibro Technology with VibroJet® Technology represents an important step toward reliably installing monopiles to full depth with minimal noise generation, said Hein van Opstal, Business Development Director at GBM Works. “We are proud to be part of this groundbreaking approach.”

Supporting broader adoption of low-noise techniques in future wind farms worldwide

By comparing these innovative approaches with traditional impact hammer installations, researchers will measure differences in performance, pile stresses, and noise generation. Data collected will also validate predictive models for underwater sound and pile behaviour, supporting broader adoption of low-noise techniques in future wind farms worldwide.

"Our ambition is to build offshore wind farms in harmony with nature," said Folkert Visser, Project Director at Ecowende. "Through these demonstrations, we expect to show that innovative technologies can be applied in practice while minimizing the impact on the marine ecosystem."

Towards a future where marine life and clean energy thrive together

By advancing low-noise installation methods, Ecowende aims to set a new standard in eco-friendly offshore wind construction. The combination of Vibro and VibroJet® technologies has the potential to replace traditional impact hammers, reducing underwater noise and safeguarding marine biodiversity — proving that sustainable energy and healthy oceans can grow hand in hand.