CAPE Holland

The CAPE Holland Vibro Lifting Technology plays a crucial role in supporting the ambitious ecological objectives that enabled us to secure the Ecowende wind farm permit.

As one of the innovative solutions implemented in this project, the CAPE Vibro Lifting Technology will significantly minimize piling noise compared to conventional hammering methods. Furthermore, at three foundation sites, the CAPE Vibro Lifting Tool will be enhanced with ‘jetting’ as part of an additional test.

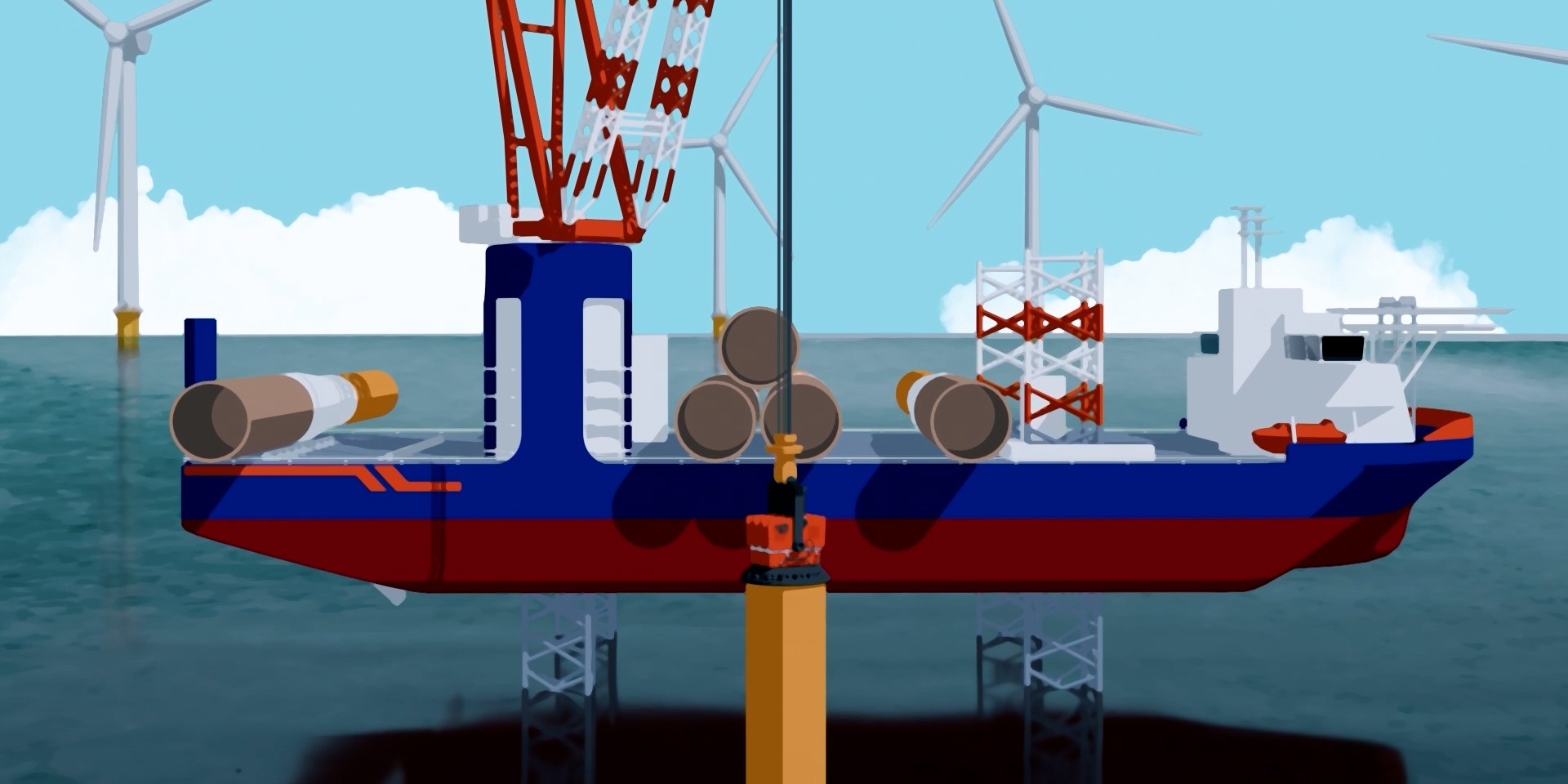

Installation of monopiles with CAPE VLT-640 Quad

CAPE Holland will supply and operate a Vibro Lifting Tool (VLT) to Van Oord, who will use it to drive the monopile foundations into the seabed with the Boreas installation vessel. All the equipment that is needed to operate the CAPE VLT is designed and built by CAPE Holland and includes the hydraulic power units, hose reels and advanced control and monitoring system.

Global leader of the Vibro Lifting Technology

CAPE Holland has been the global leader and developer of the vibro technology specifically for the offshore market for over 15 years and built up a large track record of applying the technology in the energy markets, including offshore wind. Some current and previous offshore wind projects where the CAPE VLT has been used are: Hai Long, Formosa 1 and 2, in Taiwan, Kaskasi in Germany, Moray West in Scotland, Ishikari in Japan and Coastal Virginia in the USA.

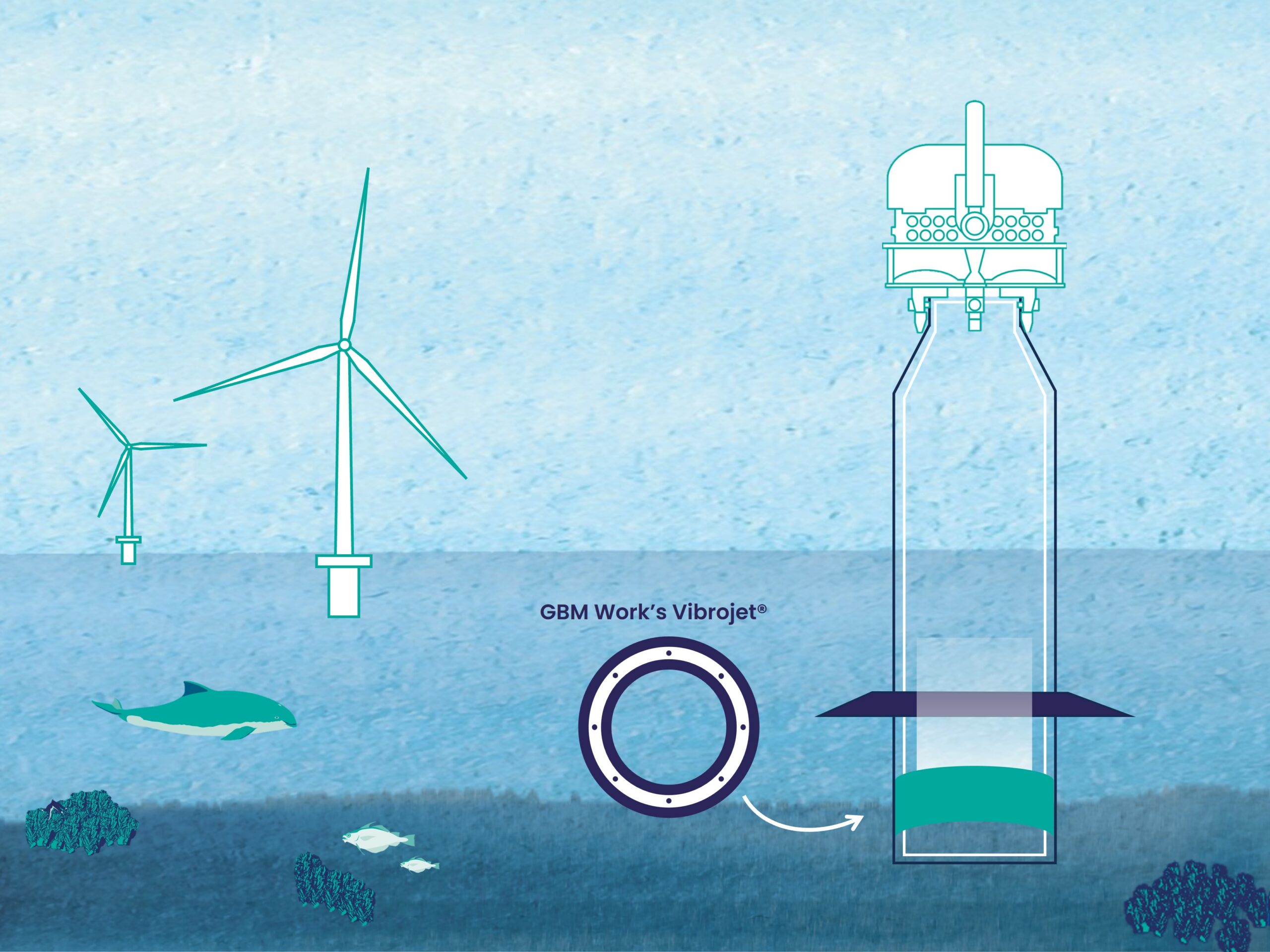

Vibrojetting

At most of the recent offshore wind projects, the Vibro Lifting Technology was used mainly to prevent pile run, but what makes the Ecowende wind farm special is the fact that it is allowed to drive the piles to final penetration with a vibro. Although this is the aim, predictions show that this will not be possible in all locations where the final part will be driven with a traditional impact hammer.

At three locations, Vibrojetting of partner GBM Works will be added to the vibro driving with the aim to be able to drive piles deeper than with vibro driving alone. The long term goal is to be able to offer vibro driving to final penetration with or without additional technologies to be used at most of the future projects to eliminate the emissions of underwater noise as much as possible. Ecowende will be an important project to make this possible.

© Images and copy in cooperation with CAPE Holland.

innovations

Related articles