GBM Works

GBM Works is one of our key partners when it comes to limiting noise during monopile installations. GBM Works is developing the Vibrojet®, a more silent installation method for offshore foundations that reduces the environmental impact on marine life. For the Hollandse Kust West (HKW) Site VI wind farm, GBM Works is responsible for, amongst others, the engineering and manufacturing of the jetting system and offshore support during the installations. To execute the project, GBM Works is also working closely with our other partners Van Oord, Sif and Ramboll.

Installation of three monopiles with the Vibrojet®

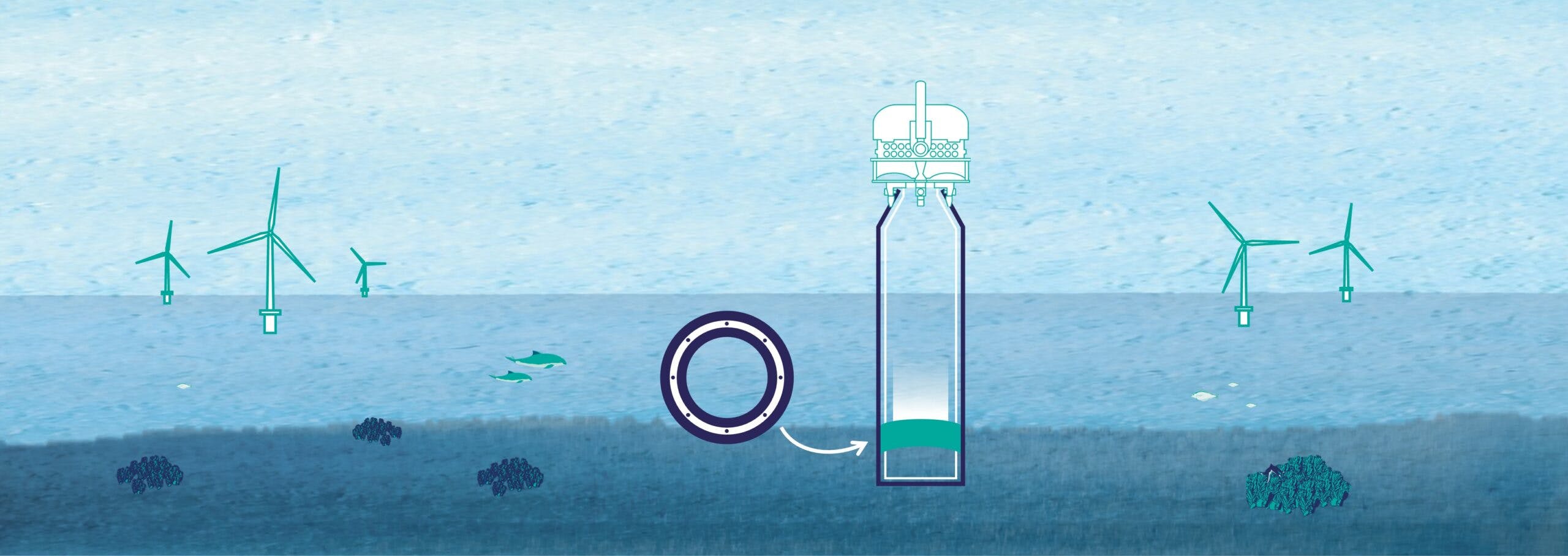

The Vibrojet® is an innovative solution that combines vibrations on the top of the monopile with water jetting inside of the monopile. The combination reduces resistance from the soil during the installation, making the installation more efficient and limiting the noise levels emitted compared to those emitted from traditional installation techniques. This also limits the disturbance to marine life.

In addition to the ecological benefits, the Vibrojet® also provides several operational benefits. In comparison to the traditional impact hammer, the Vibrojet® allows monopiles to be installed quicker. In comparison to the Vibro-hammer only, the Vibrojet® allows monopiles to be installed deeper.

This is the first commercial offshore wind project where the Vibrojet® technology will be used. The depth of the North Sea and the soil types on site, combined with the use of extra large monopiles, closely resemble the condition for which the Vibrojet® has been designed. This makes Hollandse Kust West (HKW) the ideal site to demonstrate the technology offshore.

Development of the Vibrojet® technology

GBM Works has been developing the Vibrojet® technology since 2016 – a technology born from GBM’s mission to accelerate the energy transition by developing and commercializing a silent installation method that reduces impact to marine life. The Vibrojet® configuration used at HKW has been developed in the Silent Installation of Monopiles (SIMPLE) projects, a series of development projects to test and improve the technology. Think about extensive lab tests and optimising existing fluidisation models used to predict the behaviour of the soil inside the pile during installations.

SIMPLE III

The latest development of the Vibrojet® is happening in SIMPLE III. In this pilot project, the Vibrojet® will be tested ahead of commercial installations in the Ecowende wind farm. The tests focus on the drivability of the Vibrojet® and noise measurements to quantify the reduction in noise levels when compared to that of traditional installation methods.

Upon completing the large-scale tests of SIMPLE III, the Vibrojet® will reach Technology Readiness Level (TRL) 7. The TRL scale reflects the maturity of a certain technology, ranging from 1 to 9. TRL 7 indicates that the technology has been successfully demonstrated in an operational environment providing lessons for commercial implementation.

Ecowende supports the SIMPLE III project by providing funds and the opportunity to test the technology at the HKW site. We also advise GBM Works via the project’s steering committee group together with other industry players.

© Images and copy in collaboration with GBM Works

innovations

Related articles